A Riveting Tale About Rivets: How to Use Blind Rivets

Rivets are used to permanently join together individual pieces of material, such as metal, tough plastic, and other hard materials. Blind rivets - also known as pop rivets - allow fastening of materials that can only be accessed from one side, while being ‘blind’ to the opposite side.

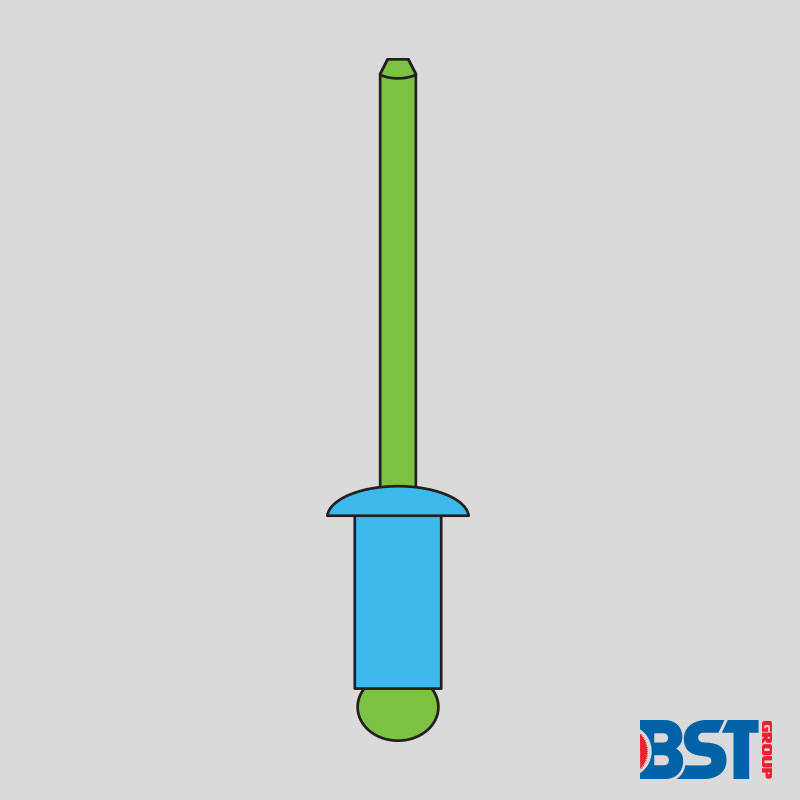

They are composed of the rivet (shown above in blue) and the mandrel (shown above in green).

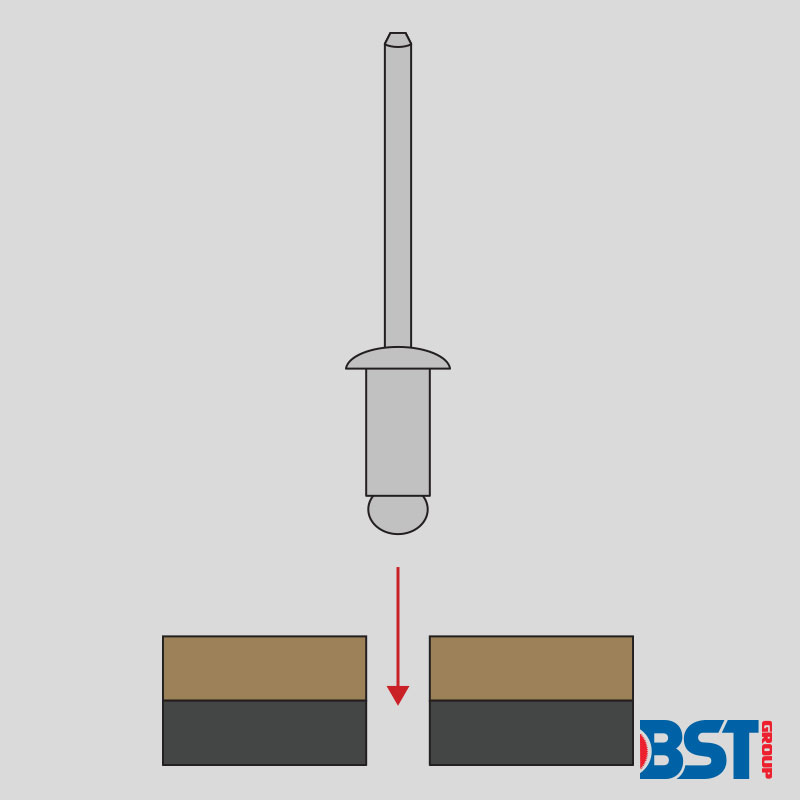

Blind rivets are installed in a tight hole between the materials being joined.

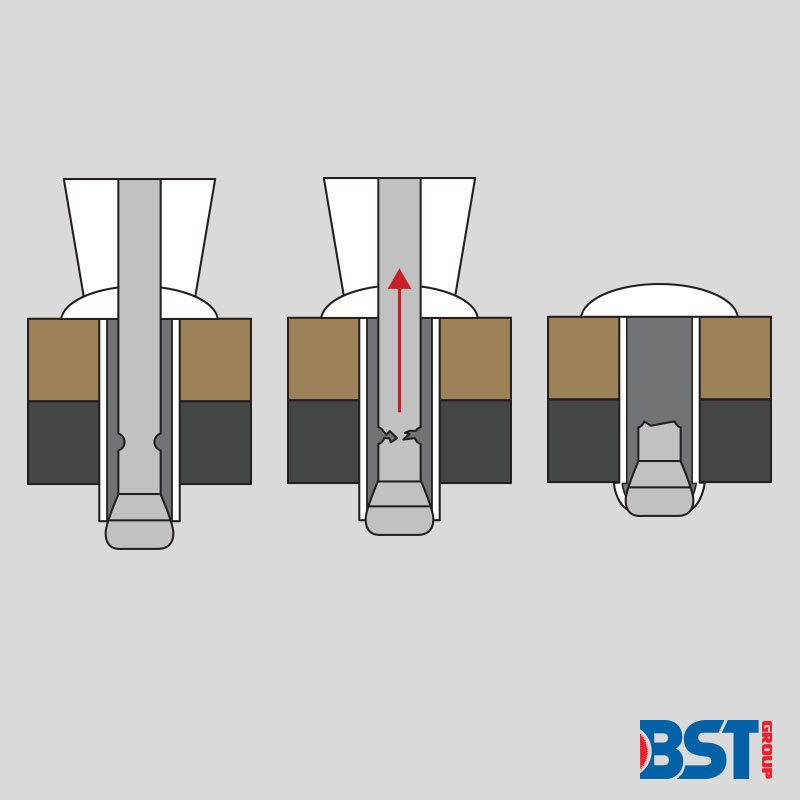

Open the handles of the riveter and insert the mandrel, making sure that you are using the correct sized nozzle to fit the rivets you are installing.

Squeeze the handles, bringing them as close to each other as possible. This will pull the mandrel back while holding the rivet in place.

As the mandrel is pulled back it pushes the sides of the rivet outward until the mandrel snaps. This bulge forms the blind side of the rivet and holds the materials together.

Blind rivets are available in different head styles like dome, large flange, and countersunk.

They are also available in a number of different combinations of materials:

> Aluminium Rivet & Aluminium Mandrel

> Aluminium Rivet & Steel Mandrel

> Steel Rivet & Steel Mandrel

> Stainless Steel Rivet & Steel Mandrel

> Stainless Steel Rivet & Stainless Steel Mandrel

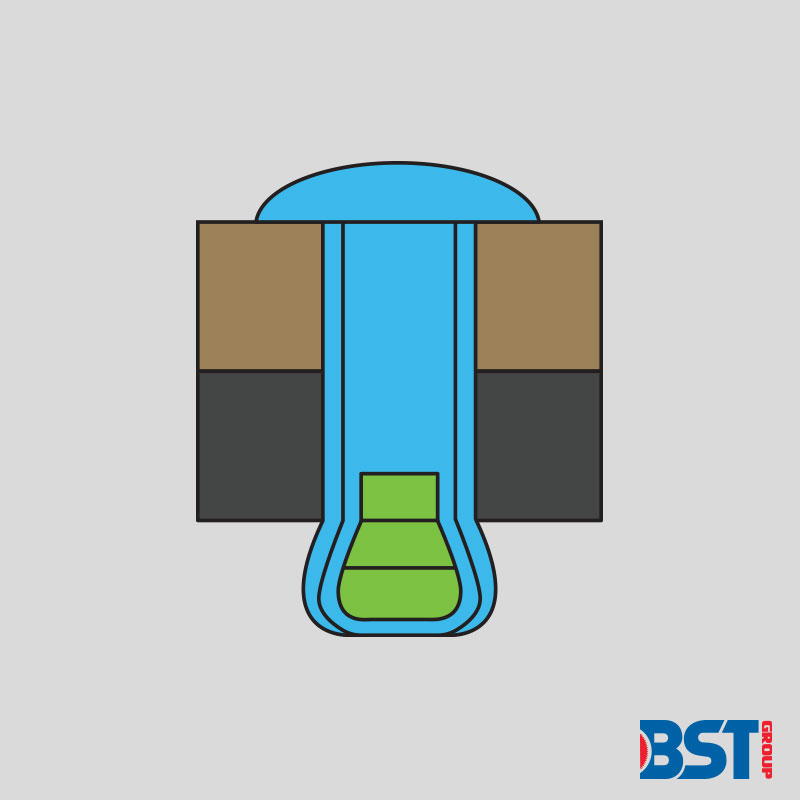

Because the mandrel (green) remains in the rivet (blue) it is often recommended to use matching mandrels and rivets to avoid issues with corrosion. If you are not sure, the best advice is to ask the BST experts for recommendations when buying rivets.

Important Notes

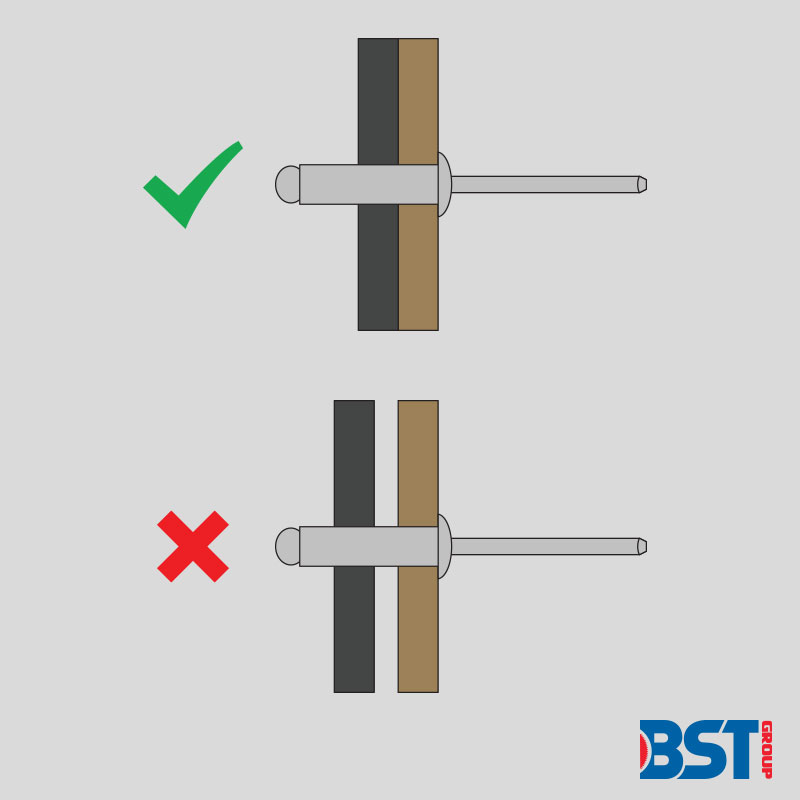

It is important to note that you should not pull the materials together by riveting them. Instead they should be used to fasten materials that are already held together with, for example, clamps. If you do not follow this step, then it is likely that the rivet will bulge in between the materials, which is a pain to remove because you will need to drill it out, therefore creating a larger hole than the original.

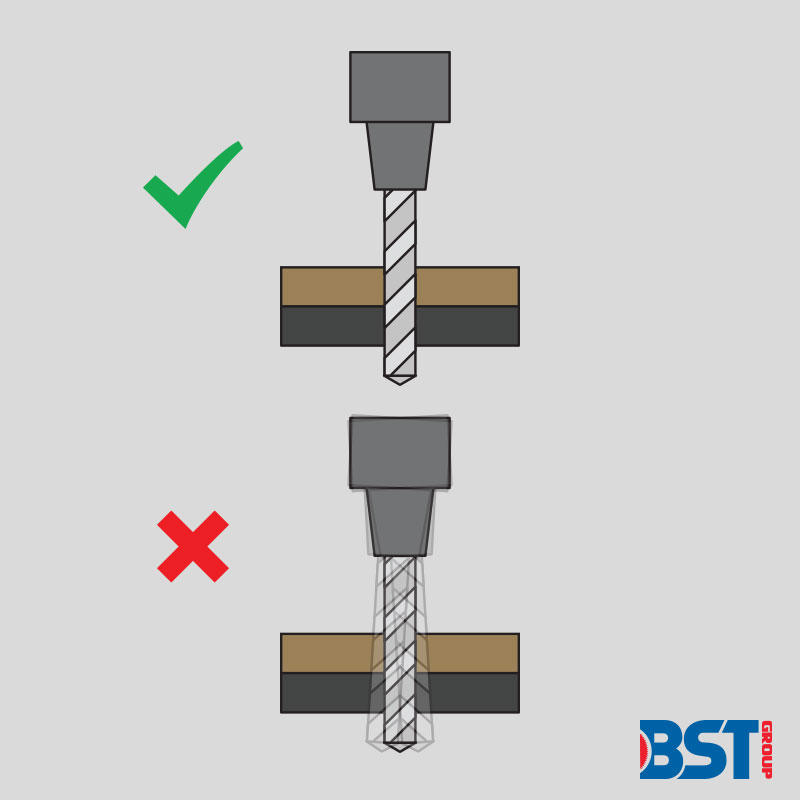

Also, make sure to use the exact drill bit, and try not to wobble while drilling. Correct hole size is a must, because even a small increase in hole size can mean reduced holding strength.

BST Group stocks a range of rivets in various types, materials, and sizes. The types include dome head, countersunk, large flange, sealed, and coloured, while the materials include aluminium, stainless steel, and steel. We have a full selection of sizes in each of the types, and are sure you will find a rivet to match your needs.